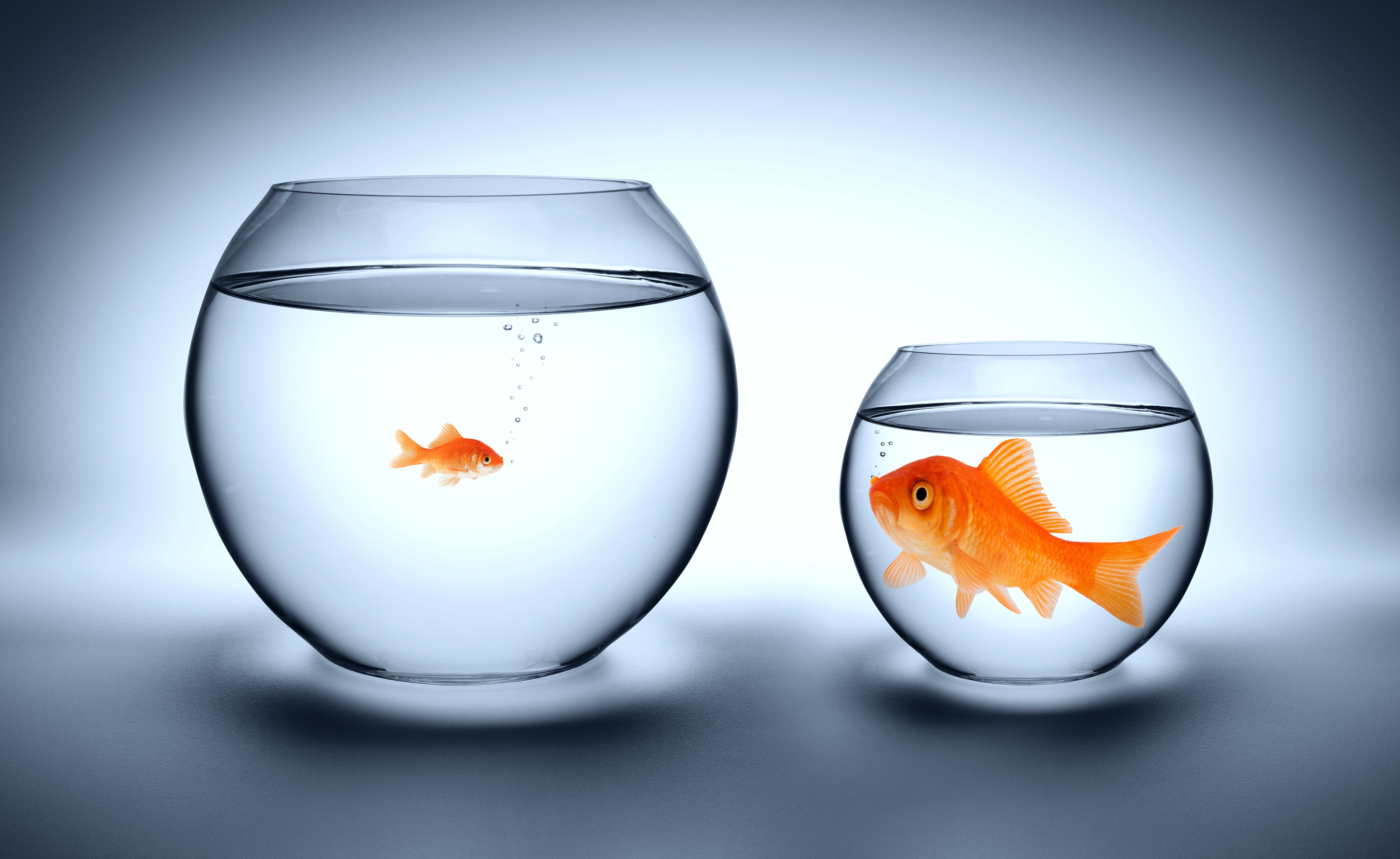

When it comes to packaging and converter supply orders, nobody likes when a bigger fish comes in and gets first priority, pushing your “small fry” order of just a few thousand units down the queue. We see it happen all the time. In a world that now hinges on the maze-like nuances of packaging and transportation, if you’re considered a minor customer to an international/multinational supplier (think Bemis, Sealed Air, and Printpack) it could lead to a procurement person’s worst fear: an interruption in their production lines.

The reality is that internationally recognized brands able to capture the lion’s share of capacity from packaging suppliers - receiving the maximum amount of attention and priority to keep their products circulating. The same can’t be said for a smaller business. With private label brands and regional businesses trying to match the quality and format of the most well-known competitors in the industry, they need suppliers who will treat them with the same deference - like a big fish. Luckily, in our experience negotiating supplier contracts, size is relative. It is possible, and even preferable, to become the biggest fish in your pond.

Packaging Supplier Options

Knowing that the biggest converters aren’t going out of their way to support regional or private label brands, who can smaller manufacturers look to? Lead-time clauses are practically non-existent for small brands or businesses, and even if negotiation can be reached, the end result is a lead time too long to be reasonable, with unsatisfactory results.

Though some think it so, working with a lesser-known, second-tier converter does not translate to less quality. The idea of working with a recognizable big name can be appealing but, let’s face it, there’s no real benefit if such a supplier leaves you stranded. Local, private, smaller businesses are responsible for a material percentage of the United States’ employment and economic growth. Those that succeed have found a way to differentiate themselves - offering customers something they cannot easily find elsewhere.

Such is the case with regional converters who often go out of their way to purchase state-of-the-art equipment, allowing for less human labor and faster turnaround times. In many cases they are capable of delivering the same or better results (and contract terms) than the big brands many seek. Further, as packaging becomes more and more complex, converters are continuously popping up and expanding to fulfill a variety of niche demands. Chances are, there’s an ideal partner out there for each business.

Change Can Feel Risky

There are so many different concerns in keeping a production line going that even considering changing supplier options can be overwhelmingly complex. Take, for instance, converting - a process that spans multiple packaging concerns from printing, to assembling pre-printed pouches, to attaching zippers and other closure-apparatus. Understandably, moving such a complicated process to another provider feels risky.

To a degree any action, and even a lack of action, can be risky, especially if you are not in the top 10% to 20% of volume purchasers and therefore, run the very real risk of finding yourself floundering without the product you need. Additionally, seeking a partner experienced in evaluating and negotiating with suppliers that can remove the risk of an idled manufacturing line can, naturally, provide tremendous value-add by applying their subject matter expertise.

The Bottom Line: While familiar, big supplier names come to mind first, smaller businesses are much more likely to succeed in both cost and manufacturing efficiency when they partner with vendors who can give them the care and attention they need to be efficient. SRM can help your business review the options; we closely analyze how the industry changes, and have established a network of resources to safely compare the options, without line interruptions. Get in touch with us today and see how we can set you up with the perfect match.

For more on this topic, read Efficiency: One of Packaging and Transportation’s Biggest Hurdles.